The manufacturing industry is consistently moving towards deeper automation across industries. Certain tasks, like industrial cutting, lend themselves to automation. This application is commonly automated with solutions ranging from robotic automation to purpose-built machinery. Whether it is a flying shear on a bagging line or a plasma cutting application, it can be automated with robotics. In this article, we will explore the types of cutting robots, how to integrate one, and the challenges associated with this task.

Types of Cutting Robots and Their Applications

Cutting robots come in all forms. This is thanks to the broad range of tasks and the industries in which they’re found. Simpler tasks demand different requirements of the hardware and software than more complex tasks. Luckily, cutting is a standardized application. This means it is one commonly solved with robotics. But what cutting tasks are automated, by which robots, and in what industries are they found?

Cutting Tasks

While cutting might be considered a subset of machining, it is still a broad application category. Cutting tasks vary widely depending on the industry. On top of that, the material being cut is a major factor in the type of cutting to be done. Some common cutting tasks include:

- Shearing

- Water jet cutting

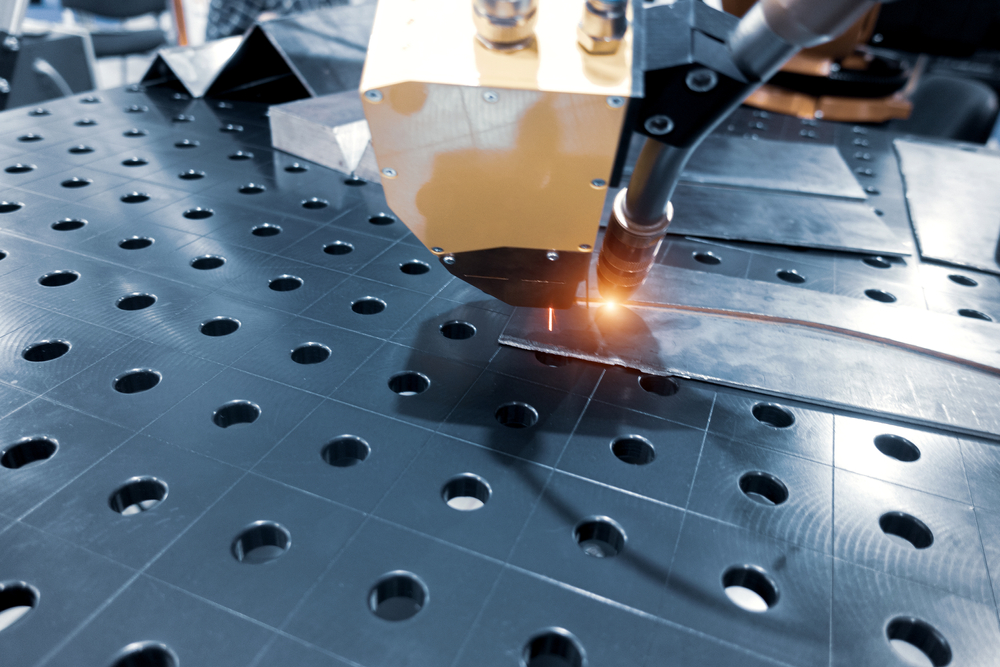

- Plasma cutting

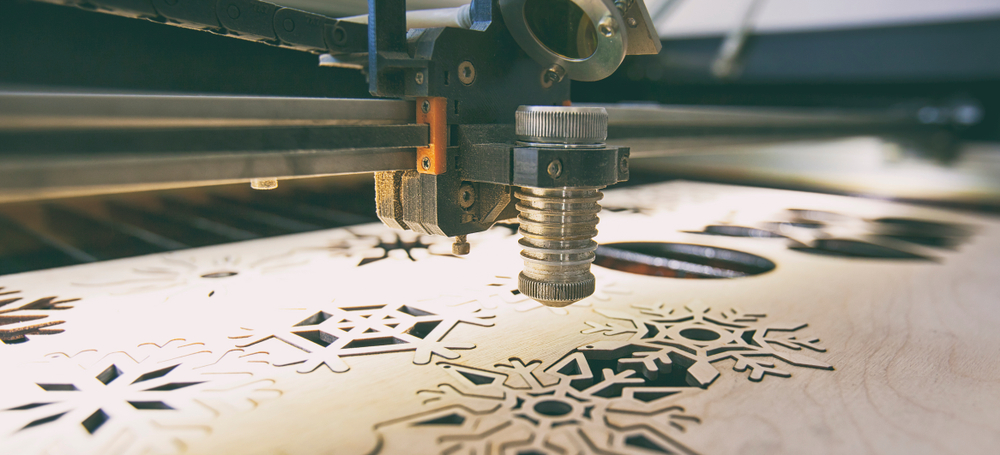

- Laser cutting

- Oxyacetylene cutting

There are even subsets of these categories! For example, there are several different types of laser cutting methods. The requirements of your application will inform which one is right for you.

Cutting Robot Types

The robot type is selected via the demands of the task. Since each robot type has its own strengths and limitations, the specific attributes of your task should lead you to choose the most optimal hardware. The type of robot and tools used to cut fabric might be completely different from one used to cut several meter long sheets of metal. That being said, some robot types you will often find in cutting tasks include six-axis, collaborative robots, SCARA, and cartesian. This isn’t to say that other robot types can’t do the task. These robots have a good balance of reach, speed, and precision. Additionally, many cutting tasks are in a single plane, which these robots are good at operating in.

Industries for Cutting Robots

Many industries are already capitalizing on automating their cutting processes. Cutting robots are offering them an edge over their competitors by providing productivity and quality gains. Additionally, robotic automation is helping them to enter industry 4.0. These industries include:

- Metals

- Aerospace

- Plastics

- Construction

- Foam Polymers

- Paper

- Fabrics

One thing these industries have in common with their cutting tasks is that they are often high-volume and repetitive. Most robotic automation projects are found in this space of volume and repetitiveness. Industries like metals and plastics are creating thousands of pieces a day. Tasks like this should be considered first when looking for potential automation projects.

How to Integrate a Cutting Robot

As with any robot project, there are many considerations beyond which robot to choose. Cutting is a task that requires a specific solution. Making the wrong choice here can potentially have large financial repercussions. The tools used for cutting can be very expensive. Choosing the wrong one can hurt financially.

When to Consider Automating the Cutting Task

Many people consider robot projects for similar reasons. They need higher production, less waste, more efficiency, etc. Telltale signs include factors like:

- Inability to keep up with production demands

- Producing too much scrap after every production run

- Needing higher uptime/lights out manufacturing

- Making the cutting process safer

Applications that don’t currently reflect any of these issues will have a hard time providing an ROI for your investment.

How to Choose

Your robot and associated hardware need to be task specific. What that means is that you should start with the task and work back to the robot and tools required. For example, if you are cutting large pieces of metal need to do it quickly and precisely, a cartesian table with a plasma or laser cutter might be best. If you are cutting 1 square meter pieces of fabric, a six-axis robot with mechanical shear might be best for you.

Who to Contact

Who to contact for robotic services can be a daunting task. There are more providers and brands than we could possibly choose from. However, at minimum, you will need a brand and a provider to sell you those parts. Unless you are taking on the robot integration task yourself, you want to consider reaching out to integrators. Robot integrators are experienced in solving complex robotic engineering tasks. It is very likely that several providers you reach out to will have done an automated cutting task before.

Did you know that HowToRobot is one of the easiest ways to quickly get in contact with suppliers in your area? We help you get connected with solution providers and get price indicators back on a variety of solutions. Get a quote today right here.

Automation Challenges

Like any automation task, there are challenges associated with cutting tasks. It is important to understand the common points of failure. This way, you are less likely to make these mistakes yourself. Common challenges are around concepts like precision, end of arm tooling and part presentation.

Precision

Different robots have different levels of precision. This precision is often given by a repeatability metric in the documentation. Precision can make a difference in the quality of your cut parts. Additionally, it can determine whether or not you can stay in tolerance for that part. Precision can be due to a number of factors. Very often it is a result of backlash or use of stepper motors instead of servos. Being unaware of your robot’s precision measurements before integration can cause you to create failed parts if the required tolerance is high.

End of Arm Tooling

End of arm tooling is crucial to the integration process. Many cutting tools are designed for humans. However, there are plenty of tools available for robots as well. These devices are usually available from the integrator or manufacturer. You want to ensure that there is available end of arm tooling for the type of cutting you want to do. Additionally, it’s important to ensure this tooling is compatible with your robot. This compatibility is in regards to mounting and communication. Without this, your tool isn’t going to help much.

Part Presentation

Proper part presentation is crucial for long-term cutting automation success. Cutting is typically a precision activity. This means it is meant to operate repetitively within tight tolerances. It often requires that the same thing be done every time. So, ensuring your parts are arriving to the robot in the exact same way the program was written is important. An offset in part presentation could lead to several inches of error in the final part.

Cutting technology is advancing rapidly in the industrial automation space. With the popularization of collaborative robots, be on the lookout for more hybrid-friendly cutting automation tasks in the near future.

Have a budget? HowToRobot has tools that help estimate your costs and develop KPI models to understand what metrics you would need to hit in order to see a return on investment. Use our investment calculator to start building your budget.